Sydney University is the oldest university in Australia, having been founded in 1850 and State Heritage Listed in 2018. Its combination of tradition and innovation in the academic sphere is emulated in its construction, with sandstone halls and glass theatres alike providing an architecturally diverse space for students to learn, grow and thrive.

Sydney University values safety, performance and environmental protection. Masterflow ensured that our supplied system offered minimal risk of on-site injury, excellent efficiency for saving both on costs and emissions, and optimised performance.

- Location:Camperdown (NSW)

- Industry:Education

Our Process:

As Masterflow ascertained the client’s brief, design and drawings were produced in-house using industry-leading software, executed by our experienced engineers.

Once design and drawings are complete, fabricated steel work is manufactured in our factory, where every skid mounted pump set is assembled in-house. The nature of both design and manufacturing being actioned in-house results in greater communication and direction between engineers and fabricators, achieving superior results.

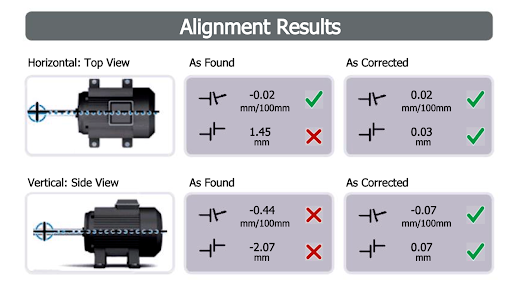

We then performance tested the system and provided test certificates to this client. All Masterflow customers are welcome to request the same process if their schedule permits. Our Quality Assurance department provides documentation for all aspects of the build, including the pumps, motors, coupling, skid mounts and inertia bases on this job.

Finally, installation is carried out. Using prefabricated units means that installation is drastically more time efficient than the traditional process of delivering and fitting pumps, then delivering and fitting tanks, *then* installing pipework. Only one crane, one electrician, and one plumber were required for this job to be completed, saving on budget due to reduced labour costs thanks to less tradies working for less time, as well as a reduction of potential errors thanks to the tested arrangement achieved through a prefabricated setup.

Outcomes:

The installation process was streamlined for this project thanks to the client’s choice to use prefabricated skids. This resulted in a sharp decrease in time spent on-site, creating significant cost savings on labour for the client with no compromise on product or installation quality.

Thanks to the system efficiency afforded by the use of a prefabricated unit, all parts were sourced from Masterflow as the sole supplier and designed to work as one unified whole. This allows the client to deal seamlessly with one provider, who delivers all materials together, rather than experiencing the chaos of managing deliveries from various suppliers, arriving at various times, with conflicting warranties and service teams.

The technicians were able to complete their work quickly and easily when compared to complex traditional jobs, reducing the potential for injury and human error.