Spec Check Issue 2: Plinths

Welcome to the 2nd issue of Spec Check. We hope you find it challenging and a reminder for you to review your Master Specification.

Today’s issue is about the simple and basic product known as Plinths, equipment pads or housekeeping slabs.

Over the years we have noticed with interest that some specifications include them, and others make no reference to them at all. It is considered industry standard to have a platform or pad of 100 mm high on which the mechanical equipment, such as the boiler, pumps, chiller will be placed.

From time to time we notice installations where plinths are absent – see Figure 1 as an example. The main design criteria for a plant room is to have enough floor waste exits and enough gradient so that water leaks from equipment can drain away.

Our suggestion is to review your master specification and ensure you do at least make mention of the requirement to have all equipment raised from the floor.

A good idea is to have a short paragraph describing the requirement to form a housekeeping slab or plinth under all mechanical equipment. Furthermore, to ensure a good finish, make mention of a Plinth Surround. This will save the contractor creating form work and ensures a good looking plinth with no sharp edges offering protection from damage and giving the plant room a professional look for the life of the building. See Figure 1 for the results of not having a Plinth Surround.

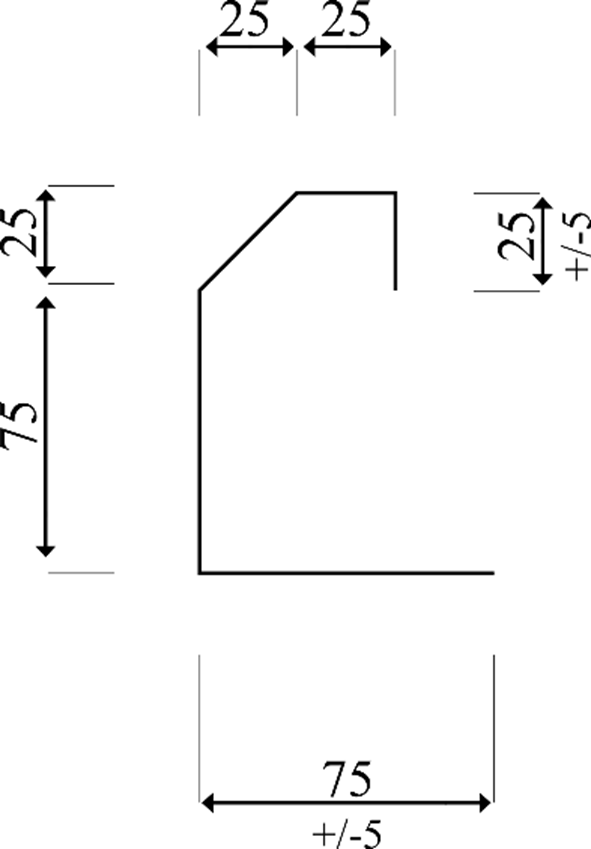

Another way to cover this is to have a detailed drawing showing the plinth surround profile and label the drawing as “Plinth Surround Detail – All equipment” (see Figure 2).

Action List:

Check your master specification today. Have you covered plinths? If there’s no mention of plinths in your master spec, consider adding a clause like the following:

All mechanical equipment to be raised off the plant room floor on a 100 mm high plinth/housekeeping slab. Exposed concrete edges are not acceptable. Form slab using a steel plinth surround with 45-degree chamfered profile. Any mitres corner joints to be painted with cold gal or similar. Refer to drawings detail for preferred profile.

Also ensure the builder or others provide floor waste exits near all equipment, especially pump strainers, chillers and boilers to take water dropped during service works.

Figure 1: These exposed concrete edges are rarely seen, but this does happen.

Figure 2: Plinth surround details – all housekeeping slabs.