Selecting the Right HVAC Motor Efficiency for Your Project

How can I select the right motor for my project’s HVAC system?

As there is no one-size-fits-all solution to selecting the right motor for your pumps, making the best decision for you is not as simple as reaching for the highest efficiency motor on the market. Because of the multitude of factors involved, including the battle between initial cost and energy usage, many have trouble in selecting a motor’s specification.

Masterflow is an experienced leader in HVAC Pumps, supplying and manufacturing pumps and motors for our client’s projects since 1998. It is in our best interest to help you avoid costly issues before they happen and to help remedy any difficulties on-site in a timely and robust fashion.

This article enables you to make informed decisions about the right motor efficiency for your needs, by describing the factors that need to be taken into consideration when selecting a motor for your pump while providing valuable calculation tools. This empowers you to make calculated choices about which components are used in your project.

What is Motor Efficiency?

The efficiency of an electric motor is the ratio between power output and power input. Because of heat transfer and other factors, such as iron and copper losses, are unavoidable, a 100% electric motor efficiency is not possible.

However, some motors are more efficient than others, using less energy to create the same performance, ultimately saving energy costs at the price of a more expensive initial purchase.

Why is Motor Efficiency Important?

An electric motor’s efficiency is important to clients because it influences the longevity, initial and operating costs, operating volume and environmental preservation that can be achieved in their investment.

Motor efficiency is legally required to meet minimum efficiency standards, which reputable suppliers, such as ABB, WEG and Teco, will ensure are never breached. Increasing motor efficiency has no downsides apart from higher initial cost and in some cases, longer lead times. When determining how high you should go, it’s important to identify your priorities between lead times, initial cost, and energy savings.

What’s on the market: International Efficiency Standards Compared

IE Standards refer to International Efficiency Standards, which are set for AC (Alternating Current) motors and PMSM (Permanent Magnet Synchronous drive Motors). IE Standards range from IE1 to IE5, with IE5 being the highest efficiency rating currently available on the market.

IE1 is decades outdated and no longer approved under government mandates. Working with MEPS-approved suppliers is a safeguard against any potential issues. This government resource allows you to ensure the supplier you’re working with is MEPS-approved.

IE2 has become the minimum standard for a motor to be considered ‘high efficiency.’

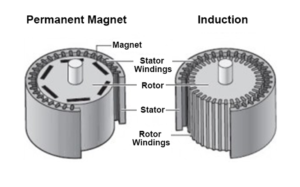

There is a notable distinction between IE2, IE3 & IE4 motors and IE5 motors. All IE2, IE3, and IE4 motors are induction motors, while IE5 motors operate through a permanent magnet synchronous motor (PMSM) or Synchronous Reluctance Motor (SR).

What’s the difference between Induction and Permanent Magnet Synchronous motors?

Most industrial HVAC systems are currently run by AC (Alternating Current) Induction motors. These are asynchronous motors that use an electrical current to drive their rotors. They are called asynchronous because the current from the motor’s magnetic field and the motor’s rotor do not run at the same speed; the rotor runs at a lower rate than the magnetic field’s electrical current.

Permanent Magnet Synchronous Motors rely on magnets to move their rotors, meaning that the PMSM’s rotor speed is synchronised with the speed of its motor’s magnetic field. PMSM (Permanent Magnet Synchronous drive Motors) motors must work with a VSD (Variable Speed Drive), which is optional in induction motors. The PMSM’s VSD will offer precise and modulated control over the system’s volume, pressure and flow.

How are IE Standards representative of motor performance?

The following table articulates the terminology typically used to describe IE efficiency quality

| Category | |

| IE1 (Induction) | Standard Efficiency (obsolete) |

| IE2 (Induction) | High Efficiency |

| IE3 (Induction) | Premium Efficiency |

| IE4 (Induction) | Super Premium Efficiency |

| IE5 (Permanent Magnet Synchronous or Synchronous Reluctance) | Ultra-Premium Efficiency |

Pros and Cons of IE2 and IE3 Motors

Given that terms like ‘premium efficiency’ can feel subjective, below are some descriptions of the advantages and disadvantages of each efficiency category:

IE2 Pros

- Initial cost-effective

- Are always available for a fast turnaround as they are stocked by various suppliers within Australia

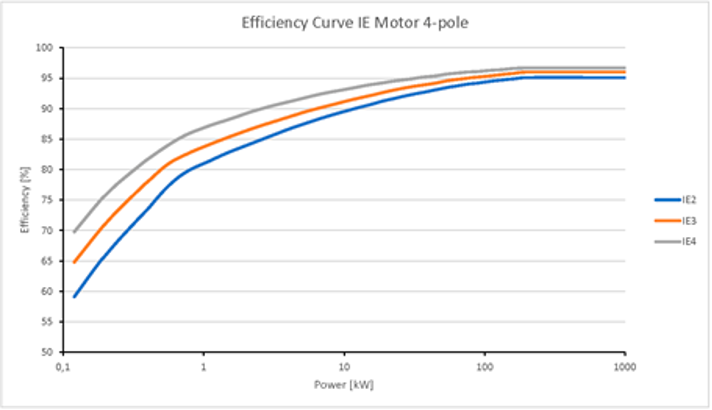

- Efficiency sacrifices begin to reduce when dealing with a high KW system. Refer to the chart below

IE2 Cons

- May be more expensive to run than an IE3 motor over extended periods of time, potentially missing out on energy-saving ROI despite low initial cost. To decide whether your project would save money by implementing an IE2, IE3, IE4 or IE5 motor, Try ABB’s Energy Savings Calculator.

- Can be noisier than higher-efficiency solutions

- Can have a shorter lifespan than higher-efficiency motors due to higher heat losses and higher operating temperatures.

IE3 Pros

- Offers a strong value proposition between the initial price and running costs

- Perform to the standard of Premium Efficiency without requiring long lead times

- Are always available for a fast turnaround as they are stocked by various suppliers within Australia

- Operates with fewer heat losses than IE2

IE3 Cons

- Higher initial cost compared to IE2 motors

- Lower efficiency compared to IE4 motors

Pros and Cons of IE4 and IE5 Motors

IE4 Pros

- Eventually, energy savings will recuperate the higher initial cost over IE3 motors, desirable depending on the client’s preferred timeframe for seeing ROI

- Operates with fewer heat losses than IE2

- Operates with fewer overall losses than IE3

IE4 Cons

- IE4 lead times can reach up to 20 weeks as motor manufacturers do not always hold stock of these motors in Australia.

- The minimum aluminium frame size of an IE4 motor moves to 100mm from the 80mm minimum of IE2 and IE3 motors

IE5 Pros

- IE5 motors offer the best efficiency and lowest energy costs on the market, particularly for clients with systems that run 24/7

- Due to their permanent magnet motors, IE5 motors can be quieter than non-permanent magnet synchronous motors

- Strong reliability and resistance to wear and tear

- The most environmentally friendly, carbon neutral conducive choice

- Are available in space-effective sizes

IE5 Cons

- IE5 lead times can be as lengthy as 30 weeks since motor manufacturers do not stock these motors in Australia.

- They are expensive from an initial cost point of view and the ROI timeframe is dependent on the individual project.

- IE5 motors require a VSD, and this VSD must come from the motor’s manufacturer for compatibility and warranty purposes.

- Permanent magnet motors are not self-starting and therefore can take longer to start up than non-permanent magnet synchronous motors.

- Spare parts and repairs will also suffer the lengthy lead times and high costs of the motor itself

- While IE2/3/4 frame sizes are often similar and interchangeable, this is less often the case for IE5 motors.

What to ensure before you buy a motor for your pump:

We do not want you to make a regretful decision. For this reason, Masterflow encourages you to ensure that the following points have been covered before you decide which electric motors will be paired with your HVAC systems.

- MEPS Approval. “MEPS” stands for “Minimum Energy Performance Standards” and is regulated by the Australian Government. DO NOT buy a motor without ensuring that its supplier and/or manufacturer is MEPS registered. Search this registration database for peace of mind that your supplier is approved.

- Energy Savings Calculation. Before paying for a motor, it is important to understand the relationship between initial price increases and energy savings over time. This can be estimated using ABB’s free energy savings calculator.

During the Energy Savings Calculation, do not forget to factor in the expected daily runtime of your HVAC system. This dramatically influences the time taken to see ROI from a high-efficiency system. The more time spent running the system, the more a high-efficiency motor will pay for itself in future.

If your system runs 24/7, an IE5 motor is a great solution. If not, it may take longer to yield ROI than desired. Similarly, the power of the system will influence the extent to which a high-efficiency motor delivers ROI. The less wattage used, the more a high-efficiency motor will pay for itself.

Make the right decision for your pump

You’ve wondered which motor choice you should make, as this decision will influence your project’s initial costs, running costs, and system operation – so it’s important to get them right.

Now that you know what to keep an eye out for when selecting a motor, you are better equipped to meet the HVAC needs of your project and to consult relevant manufacturers and distributors to move your project forward.

Moving forward, if you have any questions about which motor efficiency is best for your project or have decided on your preferred efficiency rating and are looking to move onto the next step toward completing your HVAC system, reach out to us for a comprehensive quote.

Sources:

Goman, V., Prakht, V., Kazakbaev, V. and Dmitrievskii, V., 2020. Comparative Study of Induction Motors of IE2, IE3 and IE4 Efficiency Classes in Pump Applications Taking into Account CO2 Emission Intensity. Applied Sciences, 10(23), p.10.

Detloff, C., 2022. AC Induction Motors vs. Permanent Magnet Synchronous Motors – Empowering Pumps and Equipment. [online] Empowering Pumps and Equipment. Available at: <https://empoweringpumps.com/ac-induction-motors-versus-permanent-magnet-synchronous-motors-fuji/> [Accessed 15 September 2022].