Bohle’s Trade Training Centre is centrally located in Townsville, being only a 15 minute drive from the city centre. With the Great Barrier Reef, Magnetic Island and the city’s seaside promenade surrounding it, the building is in great company.

This $37M facility trains more than 2000 trade apprentices each year, playing a key role in the wider community as its students go on to build and share their skillset after completing their programs.

The building’s mechanical contractor entrusted Masterflow with the supply and specification of the centrifugal pump used at the heart of its HVAC plantroom.

- Location:Townsville (QLD)

- Industry:Education

Our Process:

This project’s design brief emphasised the prioritisation of efficiency, as well as the use of single stage, radially split, end-suction, back pull out (BPO) pumps. We provided a 5.5kW 2 pole BakerBloc close-coupled pumpset, Model BB50-16.

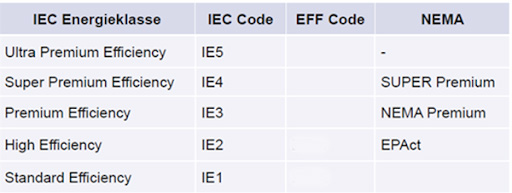

The pair of 4-pole ABB motors that Masterflow supplied meet stringent IE5 efficiency standards. IE5 efficiency means 20% less losses than the already-efficient IE4 motors, and is classified as ‘Ultra Premium Efficiency.’

The following table describes the terminology associated with each efficiency class, clarifying the terminology and hierarchy, as per the International Electrotechnical Commission:

ABB’s IE5 motors use SynRM technology to achieve this incredible performance. SynRM technology is magnet-free, making it environmentally friendly in addition to high efficiency, as no rare earth materials are used. With improved reliability, unmatched efficiency and retrofit-friendly design, ABB’s flagship motor is a powerful value proposition. To learn more about ABB’s SynRM technology, click here.

These motors were fitted with IP56 protection as per the client’s mechanical specification to ensure protection from harmful debris such as dust and water exposure.

The BakerBloc pump was mounted on a galvanised base plate, with a stainless steel drip tray fitted and tested from our factory. A 20 bar high pressure mechanical shaft seal designed to suit centrifugal water pumps was used, an important box to tick in ensuring the longevity of this high-pressure system.

Outcomes:

Our client is experiencing the best pump performance on the market, delivering return on investment with every energy bill as the ABB SynRM motor’s IE5 efficiency reduces running costs. This efficiency doesn’t just help save costs, but helps save the planet.

Optimising motor efficiency is an essential step in striving for net-zero emissions and reducing carbon offsets. We are experienced in delivering solutions that not only perform, but that do so efficiently, serviceably, and with environmental conservation in mind.