Cyclone filters vs Screen filters

Sidestream Filters in Cooling Towers

Your cooling tower plays an essential role in removing the heat from the HVAC system, and maintaining temperature conditions within a healthy range. This means efficient heat transfer and better longevity for your system, reducing maintenance costs and increasing system lifespan.

While there are some variations between cooling tower design, such as crossflow and counterflow cooling towers, the basic principle behind them is the same. They allow air to interact with the heated water, causing some of the water to evaporate, reducing the water’s temperature as it continues to flow through the system.

Cooling towers operate in a steady state condition, with water entering, and water exiting. The exiting water is broken into four categories, two of which are evaporation (of pure water), blowdown (bleeding off of cooling tower water and impurities including dissolved solids and suspended solids). Blowdown can only reduce suspended solid buildup by its concentration, meaning that any further suspended solids will build up over time, and damage the system.

For the cooling tower’s water supply to be free of debris, sidestream filtration is necessary. Sidestream filtration ensures that any particles that can damage the system once they enter your water network are filtered out from the basin of your towers.

As airborne debris sinks from your water supply to the basin of the tank, water jets positioned above the basin blast this debris to the sump. This debris is then automatically removed. Sidestream filtration thus creates a cleaner, more efficient system, and ultimately reduces the required volume of water treatment chemicals.

A tip from us to those using sidestream filtration is to request the ring pipe be installed around the basin upon ordering. This saves time on-site by simplifying the installation process.

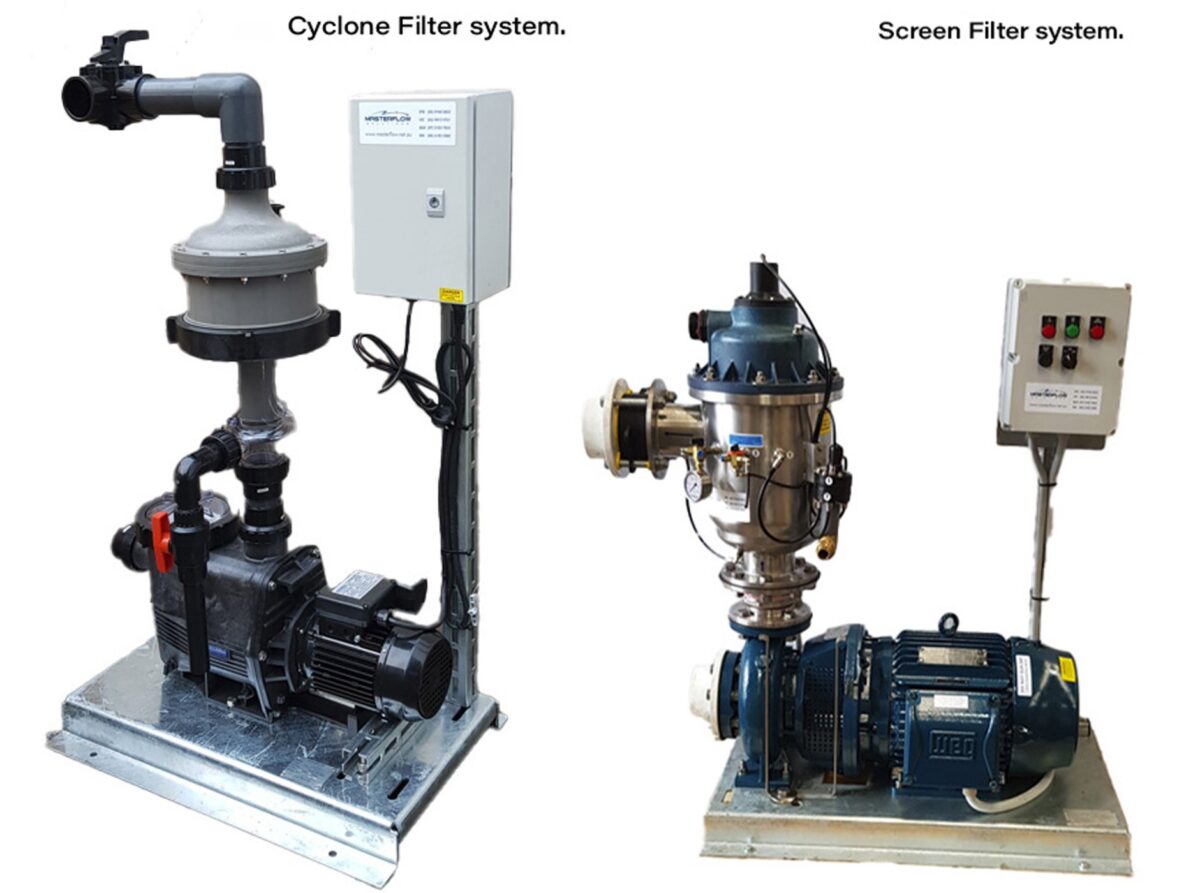

There are two primary options available for the sidestream filters used by your cooling tower; cyclone separators and screen separators.

Understanding Cyclone Filters

Cyclone filters, or ‘Hydrocyclone’ separators, remove suspended solids by spinning water at high velocity, rejecting any heavy solids by throwing out with centrifugal force. This velocity is created when the system’s water is adequately flowing, using the shape and tangential orifice of the entry point to create this cyclone effect.

Understanding Screen Filters

Screen filters use a fine wire mesh screen, and feature a self-cleaning mechanism that automatically and effectively backwashes the fine screen mesh. These filters operate on line pressure, and begin to self-clean when a preset differential pressure across the unit is reached.

Why use Cyclone Filters?

Cyclone filters are cheaper than screen filters. This leads some to view them as the go-to option when it comes to sidestream filtration for their cooling tower. However, there are plenty of reasons to reconsider opting in for the cheapest option in this case:

Disadvantages

- Cyclone filters create a high head loss (approximately 5m), draining the water pressure of your unit. This is not the case with screen filters as they operate with line pressure.

- Because cyclone separators rely on Specific Gravity, (S.G.), they are not capable of consistently preventing organic materials, such as algae, from entering the system.

- Cyclone filters will only operate when the system is running above a certain water velocity, as they can not generate centrifugal force without high system velocity.

Advantages of Screen Filters

While cyclone filters rely on high water flow to create a vortex that rejects the entry of debris and other undesirable intruders into your water supply, screen filters use a barrier that operates under all system conditions.

Screen separators are able to remove organic materials such as algae bacteria where cyclone separators cannot. Algae creates unsafe air for the end user, as well as risks of the water in your system backing up and overflowing – stunting performance and requiring hefty repair costs to remedy.

Disadvantages

Screen filters require a higher initial investment when compared to cyclone filters. However, thanks to their ability to work regardless of system pressure, their ability to remove organic materials from invading the system, and the fact that they do not create head loss, it is worth the upgrade in the majority of cases.

Moving Forward

Since anything that can be found in the air, such as dust, dirt, pollen and insects, can be inducted by a cooling tower, high importance should be placed on the specification of your system’s side stream filtration. An effective cooling tower filtration system improves cooling system performance, reliability, running costs and long term health, more than making up for the initial investment.

Both cyclone and screen separators used with a sidestream filtration system will reduce chemical treatment costs as they use captured suspended solids to absorb chemicals, and both will reduce the need for system maintenance, cleaning and down time.

A key advantage of screen separators over their cyclone counterparts is their ability to remove algae from building up in the system.

As seasonal and environmental factors influence the best choice for your system, it is wise to consult an expert before making a decision. Share your project details with Masterflow and we will ensure you end up with the right gear for the job.