The high efficiency and outstanding reliability in a compact design offers an investment with the most attractive CTO over the product’s lifetime. Not to forget the energy saving capabilities and low environmental footprint.

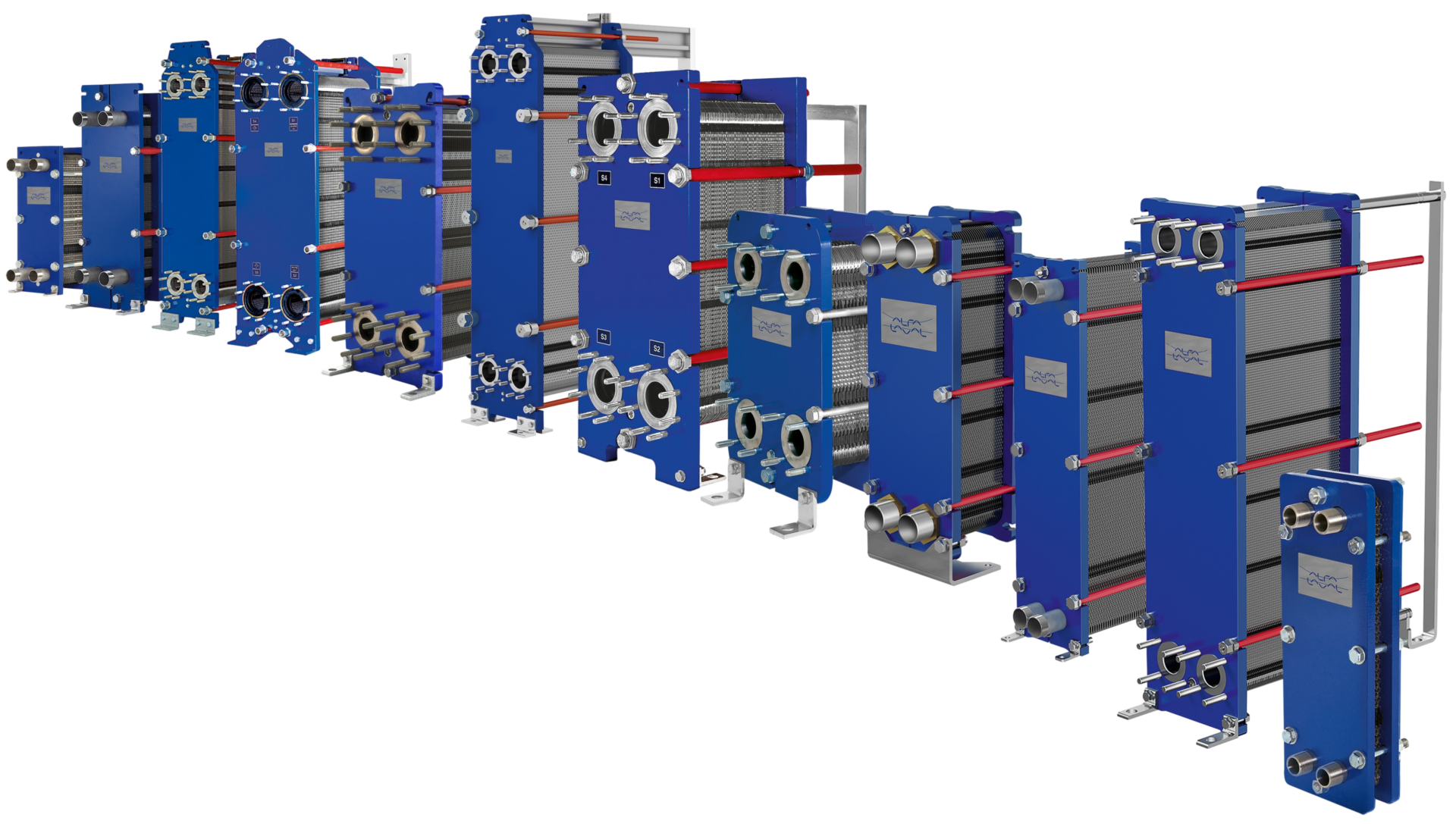

Alfa Laval’s broad range of heat exchangers includes:

- Double-wall plate

- Brazed heat exchangers

- Gasketed

- Semi-welded

- Fully-welded

Alfa Laval gasketed plate heat exchangers

Alfa Laval gasketed plate heat exchangers optimise heat transfer between large surfaces of corrugated plates, drawing heat from one gas or liquid to the other. The high efficiency and outstanding reliability in a compact design, offers an investment with the most attractive CTO over the product lifetime. Not to forget the energy saving capabilities and low environmental footprint.

Alfa Laval copper-brazed plate heat exchangers

Alfa Laval copper-brazed plate heat exchangers are a compact, efficient and maintenance-free solution for heating, cooling, evaporation and condensing in numerous applications. Each unit is designed for duty optimization, with a range of unique features that ensure both superior thermal performance and maximum reliability, even under conditions with extremely high design pressures.

ALFA LAVAL INDUSTRIAL LINE

Alfa Laval has completely redeveloped its industrial heat exchangers, setting new standards in energy efficiencies, reliability and serviceability. The number of sizes, plate and gasket materials and available options are enormous. Every detail is carefully designed to ensure optimal performance, maximum uptime, and easy maintenance.

ALFA LAVAL ALFAQ™

The Alfa Laval AlfaQ™ heat exchanger range is certified according to the AHRI Liquid to Liquid Heat Exchangers (LLHE) Certification Program which ensures thermal performance according to manufacturers’ published specifications. AHRI certification is the only global, third-party performance certification for plate heat exchangers.

Frequently Asked Questions

- What is the impact of operating my Heat Exchanger at lower flow rates than design?

Operating your plate Heat Exchanger at a much lower flow rate than its design will increase the probability of premature fouling.

- What is the fouling effect of adding additional plates (for future expansion of the plant)?

Having extra plates will help compensate for fouling, but too many plates can also assist fouling coming on because the flow is distributed across so many channels.

This could be addressed with:

a. Colder hot inlet or warmer cold inlet

b. Fewer plates/low theta

c. Smaller heat exchanger model - How should we apply a plate heat exchanger in a situation where there’s a large flow rate but only a small delta Temperature (delta T)?

Specified conditions are not ideal for plate heat exchangers. Plate heat exchangers work best when the delta T is greater than the flow rate.

In this situation, we would bypass a part of the cold side flow. This is to reduce the flow through the heat exchanger. Then we would increase the delta T.

This means return water at a higher temperature mixes with the bypassed water after the heat exchanger. Mixing the two flows gives you the correct outlet temperature. This solution requires a bypass valve.

- What is AHRI (American Heating Refrigerant Institute) performance certification for heat exchangers?

This certification helps to create a level playing field and in doing so, disqualifies some of the cheap competitors from the market.

Some companies try to work around the AHRI certification, offering stories about being affiliated with AHRI-certified manufacturers in the US. Being affiliated with these people does not make your heat exchanger AHRI-certified.All certified makes and models are listed in AHRI’s directory.

- What factors affect plate heat exchanger efficiency?

Efficiency is influenced by flow rates, temperature differences, and plate condition. Monitoring and optimizing these factors maintain peak efficiency.

- How often should plate heat exchangers be inspected?

Regular inspections, typically annual, identify and address issues such as fouling, gasket wear, or corrosion, preventing major failures.

- Can plate heat exchangers handle corrosive fluids?

Material selection, such as stainless steel or titanium, ensures PHEs withstand corrosive fluids. Proper material choice is crucial for compatibility.

Relevant Resources for Plate Heat Exchangers

GET BETTER PERFORMANCE WITH MASTERFLOW’S RANGE OF Plate Heat Exchangers

Over the decades, we’ve built ourselves on our ability to provide innovative engineering solutions that work. We pride ourselves on long-term client relationships due to exceptional service. Contact us today to see how we can support you on your next project.