Spec Check Issue 4: Full-Sized or Reduced Impellers?

Welcome to the 4th issue of Spec Check for 2019, which is a monthly publication we have initiated to commemorate Masterflow’s 21st year. We hope you find it challenging and a reminder for you to review your Master Specification, that is “check your spec!”

This issue is about the relevance of specifications. Are all your master specs up to date and are they reflective of current technology?

Because consulting engineers are covering such a wide diversity of products which make up any HVAC water system, the challenge to oversee your master specs can be somewhat daunting. To review each and every product and ensure their descriptions are relevant can be laborious and in practice can be easily left unchecked for long periods of time.

We are not suggesting that what we say is absolutely and undeniably correct as you may well have a differing opinion We believe it is healthy to constantly challenge what we are all doing in this industry, so we would love to hear your position if it varies from what is outlined here.

Two topics in the pump clauses of Tender Specifications which often catch our eye and raise the relevance question are ………

- A request or stipulation to select pumps with and impeller diameter 90% of the maximum size the casing will accommodate.

- Spacer couplings for Back Pull Out pumps

90% of the maximum size the casing will accommodate

We are curious about the purpose of such a request. Is a 10% increase in performance required as spare capacity or for future expansion?

Firstly, we do understand there are a lot of unknowns in the pipework system and therefore the designer wishes to make sure the pump is not undersized.

Secondly, it could be that the designer expects the building to undergo some expansion in the future, thus having the over sized pumps will save the building owner from having to replace capital equipment (assuming it is within 10%).

So, we ask ourselves – Is this relevant in an age where nearly every chilled and condenser water pump is fitted with a VSD? And does the designer realise this will result in a poorer pump selection with a reduction in efficiency?

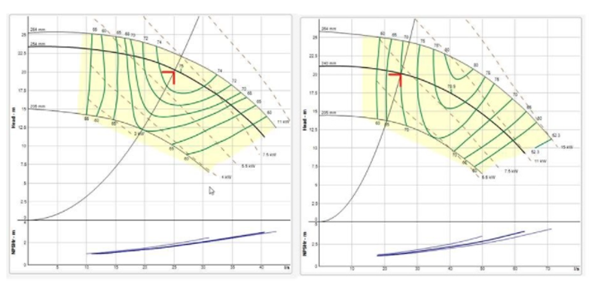

In both of the above scenarios, the spare capacity or future flow increase would be better achieved by utilising a pump with a maximum diameter impeller using a variable speed function rather than reducing the impeller to the 90% of casing size. A pump will achieve its best efficiency point (BEP) when using its maximum size impeller and a quick look at any centrifugal pump performance curve will reveal this fact. Refer to our selection program.

If you can select a pump that operates on or close to its BEP, then that pump will give a longer life of operation with a minimum number of service visits over its life that would be experienced otherwise.

The problem from a pump supplier perspective of selecting a pump with 90% reduced impeller is because it invariably means we have to go up to the next pump size where the duty point is not as well placed on the curve as was the case of the smaller selection. However, some consultants may feel that because it provides more spare capacity, it is deemed a better selection and we ask Why is it better? And what if the expansion didn’t take place for 10 years? The result is you would have a poorer operating pump for 10 years, with higher running costs that would have been the case.

Action: Review your Master specification for pumps. Does it still reflect an era that was pre VSD? If so, think about changing it.

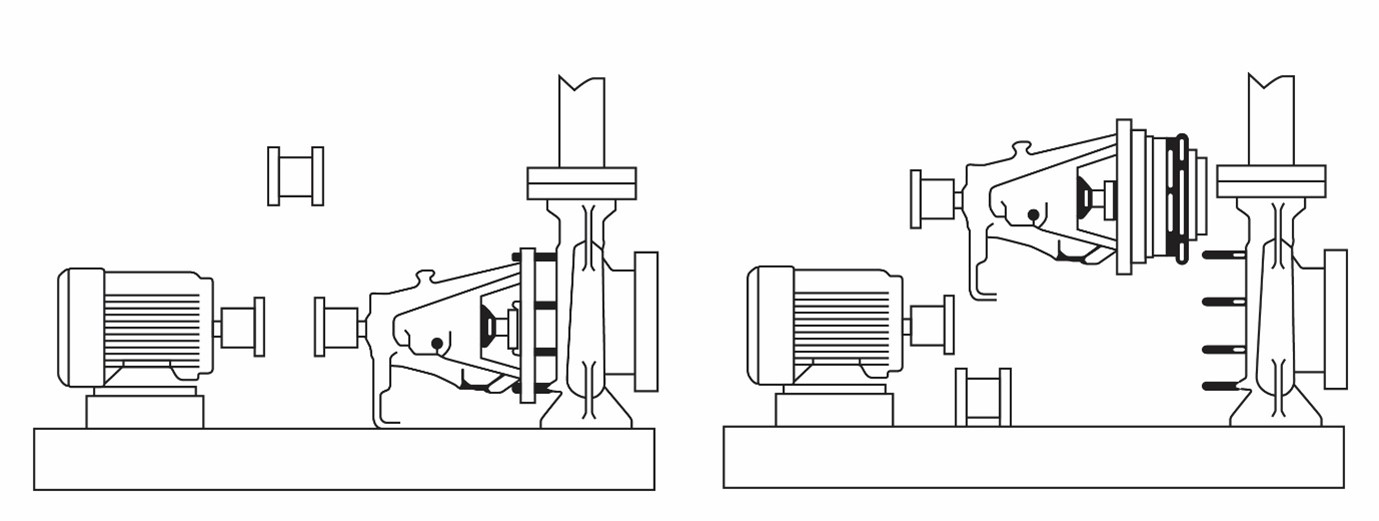

Spacer couplings for Back Pull Out Pumps

Another topic which sometimes appears in the Pump Clause of Tender Specifications is the suggestion that spacer couplings should use the Pin & Bush design. As a matter of interest, all pump manufacturers who supply the HVAC sector are using the more modern ‘snap wrap’ design spacer coupling and have been doing so since the mid-90’s.

The reason this design has overtaken the older Pin & bush type is the simplicity of changing the rubbers. There is only one snap wrap element each end of the spacer rather than multiple rubbers from multiple pins.

Leaving this in your Master is not a big deal. This is only a minor point, but the main thing to check is that you are describing the Back Pull Out feature which the spacer coupling makes possible. Our Suggestion for your specification – “A Spacer Coupling shall be used on pumps to enable the impeller to be withdrawn without disturbing the pipework connections or the electric motor”.