Spec Check Issue 3: Expansion Tanks

Welcome to the 3rd issue of Spec Check. We hope you find it challenging and a reminder for you to review your Master Specification, that is “check your spec!”

The main functions of a pressurised expansion tank (and open expansion tank) are to provide storage space for the fluid when it expands and secondly to provide a minimum or base pressure when the system is cold (i.e at minimum volume) to allow for bleeding of air at the highest point.

There are two styles of pressurised expansion tank – the bladder and diaphragm. Each has a membrane to separate the fluid from the pressurised charge, which is usually air. The airside is supplied with a precharge pressure of approximately 3 or 4 bar, to cover an ‘average installation’. The precharge should be adjusted and will determine what is available to expel air at the top point as well as the pressure required for top up water, whether it be via a refill unit or the mains water.

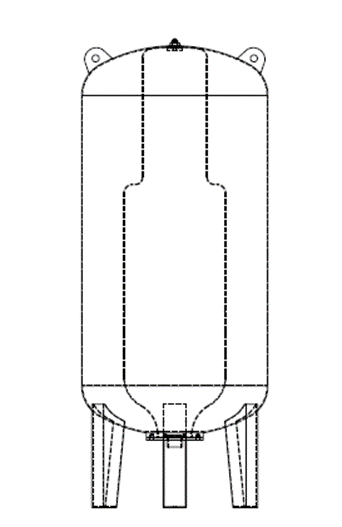

The diaphragm type has a horizontal membrane where the fluid is in contact with the tank wall. This could lead to corrosion and premature failure of the tank since makeup fluid has minimal or no direct chemical treatment. In addition, the tank is totally sealed, so a diaphragm cannot be replaced. In the bladder type, the fluid is totally separated from the tank wall which prevents corrosion and extends tank life. If a bladder does burst (e.g. allowable pressures are exceeded) the bladder on units above 100 litres, can be easily replaced through a removable plate at the bottom of the tank.

In the best interests of your client, we believe you should specify the bladder type of the expansion tank. While reviewing many specifications over the years we notice many leave it open and only a few percent of specifications nominate a bladder type. The contractor will usually install the cheapest, but the difference in price is marginal, so from a commercial perspective, a bladder style is better.

To be sure your project is commissioned correctly, and that your client receives a superior tank style we suggest you review your Master Spec and include the following:

Pressurised Expansion tanks shall have an internal bladder which fully encapsulates the expanding system fluid and does not allow it to contact the tank walls. All pressurised expansion tanks 100litre and above shall have replaceable bladders. The diaphragm style is not permitted on this project.

Pressurised expansion tanks shall be precharged with air and fitted with a correctly sized pressure relief valve on the water/ fluid side, to prevent the airside and waterside pressures being exceeded.

The airside precharge pressure shall be adjusted (up or down) to suit the water column height above the tank with adequate allowance to expel air at the top when the system is cold. The pressure switches shall be set (one to start the pump of the refill unit and maintain this minimum setting) and the others where specified, shall be set to provide alarms for low and high pressure. A blank commissioning sheet shall too be supplied by the supplier of the expansion tank and completed by the contractor to confirm the system has been set up correctly.

More questions? Contact Us here.